Voltage Regulator

|

Comments

| Voltage Regulatorsin|04 Mar : 19:20 | |

| Guest Reply to this | Does somebody have the circuit diagram of the Voltage Regulator? What should be the Battery Gauge reading when alternator is working well? |

| |||||

| Voltage Regulatorwayne|13 Apr : 06:13 | |

| Guest Reply to this | hi my e type series 3 ignition lamp stays on but only half brightness ? my control box seems to check over ok. but the at the battery terminals im measuring only around 12.6v at 1k revs and it dosent change at all? a previous owner has fitted a new alternator and it looks all correct. any ideas as to what to look for please?? |

| |||||

| Voltage RegulatorAnonymous|23 Apr : 02:50 | |

| Guest Reply to this | hi dave, i have been checking over the alternator power connections on my car, i have found a blue plastic insulator/washer fitted to the negative post, this must act as an insulator for the post and therefor fail to make electrical ground. there is no electrical wiring to this post whatsoever i reckon this is the root cause of my fault?? what do you think? should the negative alternator post make ground? according to my circuit diag it should? the positive side is connected to the terminal located by the battery. your comments are very helpfull my end. |

| Voltage Regulatorn8apu@roadrunner.com|15 Jun : 11:34 | |

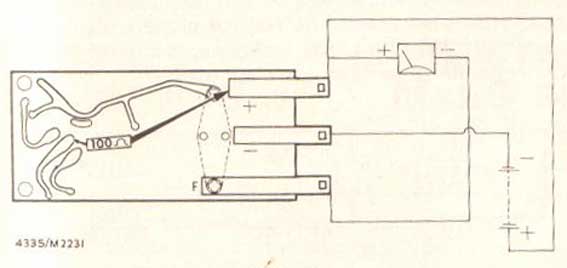

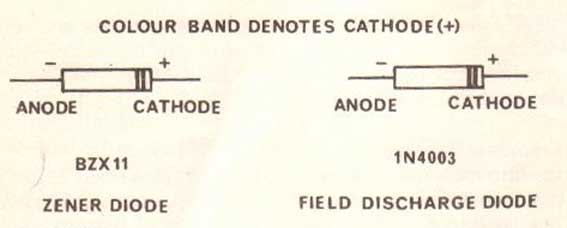

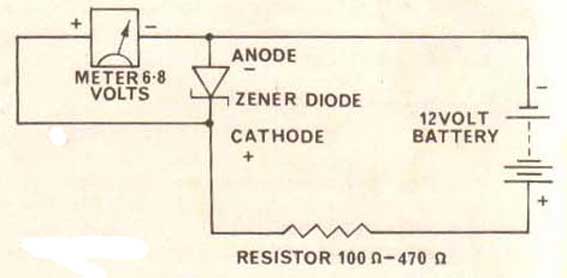

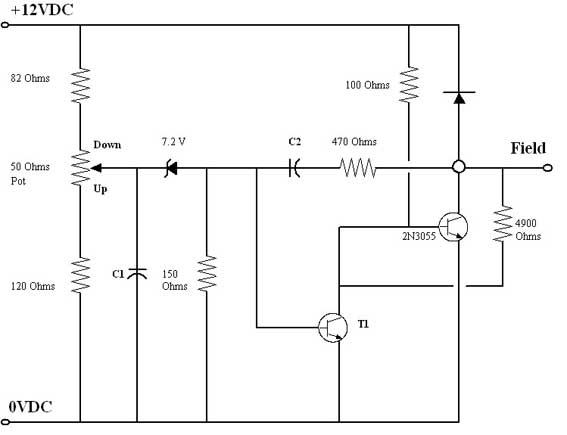

| Guest Reply to this | I have a 74. The parts are different. 1n4005, 2n3704, but i cant identify the zener, the markings on it 206? any idea |

| |||||

| |||||

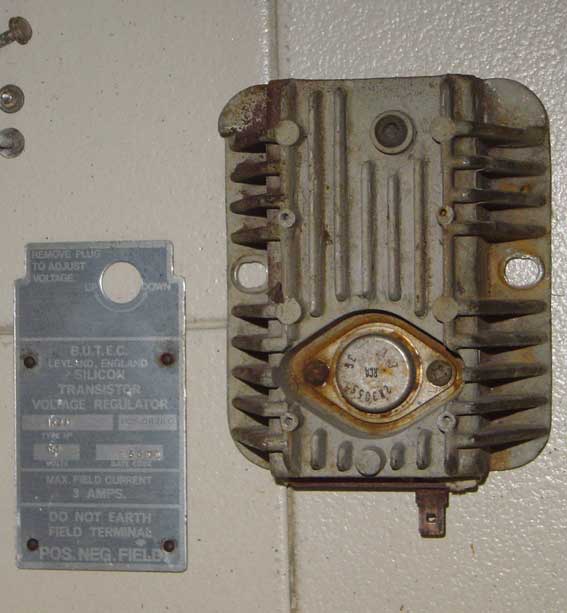

| Voltage RegulatorOV1pilot@aol.com|17 Nov : 22:35 | |

| Guest Reply to this | On the bottom of the regulator is a small, unmarked two lead component. Any idea what the component is and a replacement part number? |

| |||||

| Voltage RegulatorSimon|07 Mar : 14:27 | |

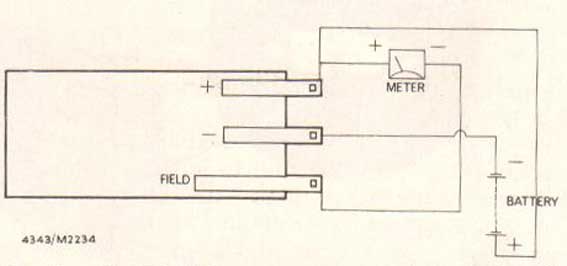

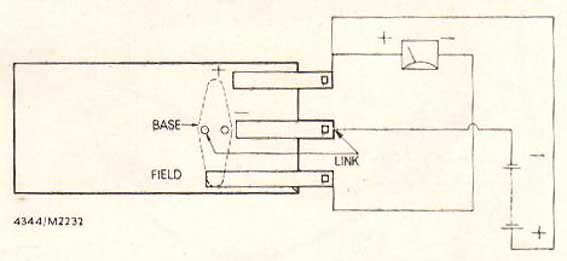

| Guest Reply to this | Hi, Congratulations on a fantastic site. I am in Australia and completing my own restoration of a 2+2 Series 3. I have alternator/regulator problems. When started for the first time, the charge light stayed on. I have tried to apply the tests described on the voltage regulator page of this site, but don't fully understand the procedure. I have 11.9 v at the battery with the engine running and all connections as normal. When I remove the plug from the regulator and join negative to field terminals, the voltage is still 11.9 v. The diagnostic manual on your site appears to indicate that the regulator is therefore not at fault. This seems hard to believe, as the alternator is rebuilt, whilst the regulator is untouched. Am I doing the diagnostic right and have you any suggestions as to where I can get further info/help? Thanks, Simon |

| |||||

| Voltage RegulatorAnonymous|10 Mar : 09:02 | |

| Guest Reply to this | Thanks for all the info! Does anyone know the caps specs? Thanks very much! Randy |

Submit comment